Dr. Hom Kandel

Currently, Dr. Kandel is pursuing his research in his Applied Physics research laboratory at the UW-Parkside with his collaborators at the University of Wisconsin-Madison, National High Magnetic Field Laboratory, Tallahassee, FL, University of Michigan-Ann Arbor, and students at the University of Wisconsin-Parkside to lead the advancements in developing and studying the properties of these novel electronic materials.

Dr. Kandel is actively involved in mentoring of several physics students at the UW-Parkside by offering financial support and programs for research through Undergraduate Research Apprentice Program and Summer Research Fellowships. With his mentorship in his research programs, several students have been able to attend local, regional, and national level scientific showcases and conferences to present their work with the scientific community.

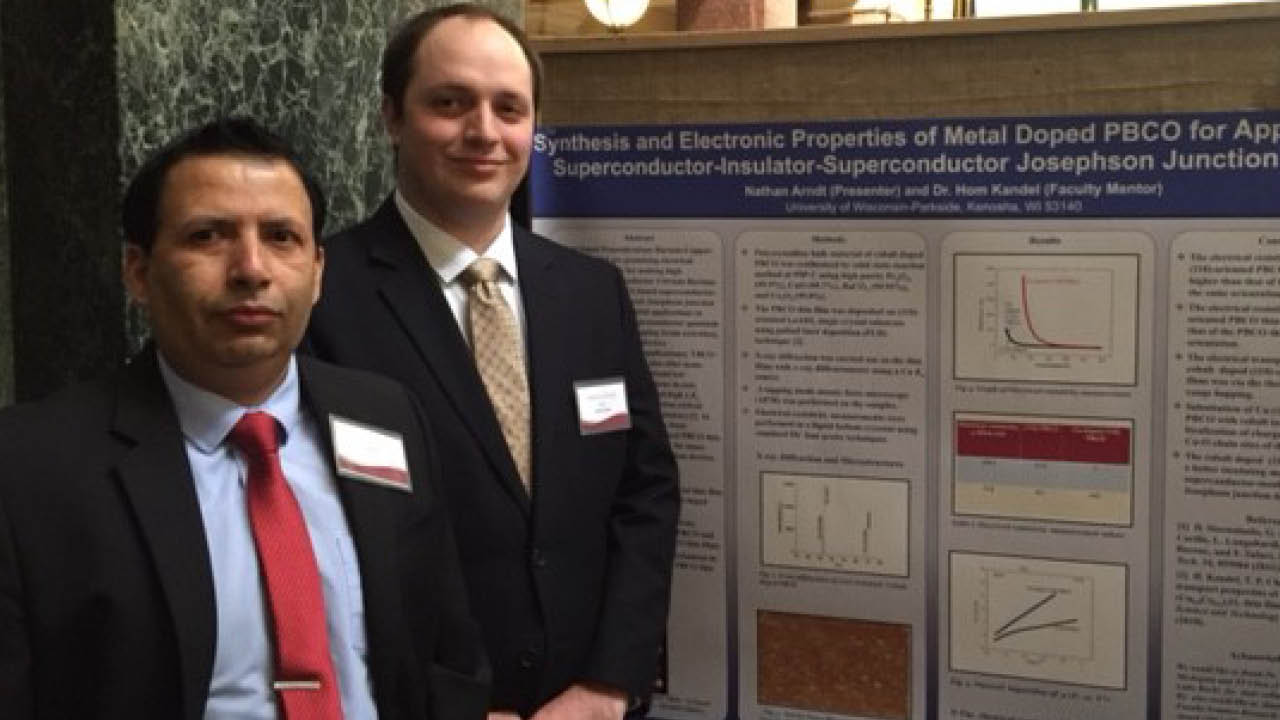

Nathan Arndt (right) has presented his research at the Research in the Rotunda 2018, UW System Symposium for Undergraduate Research at UW-Greenbay (2018), and the Wisconsin Science and Technology Conference (2018). His research work has been also approved to attend the “National Council on Undergraduate Research 2019” (NCUR 2019, Georgia).

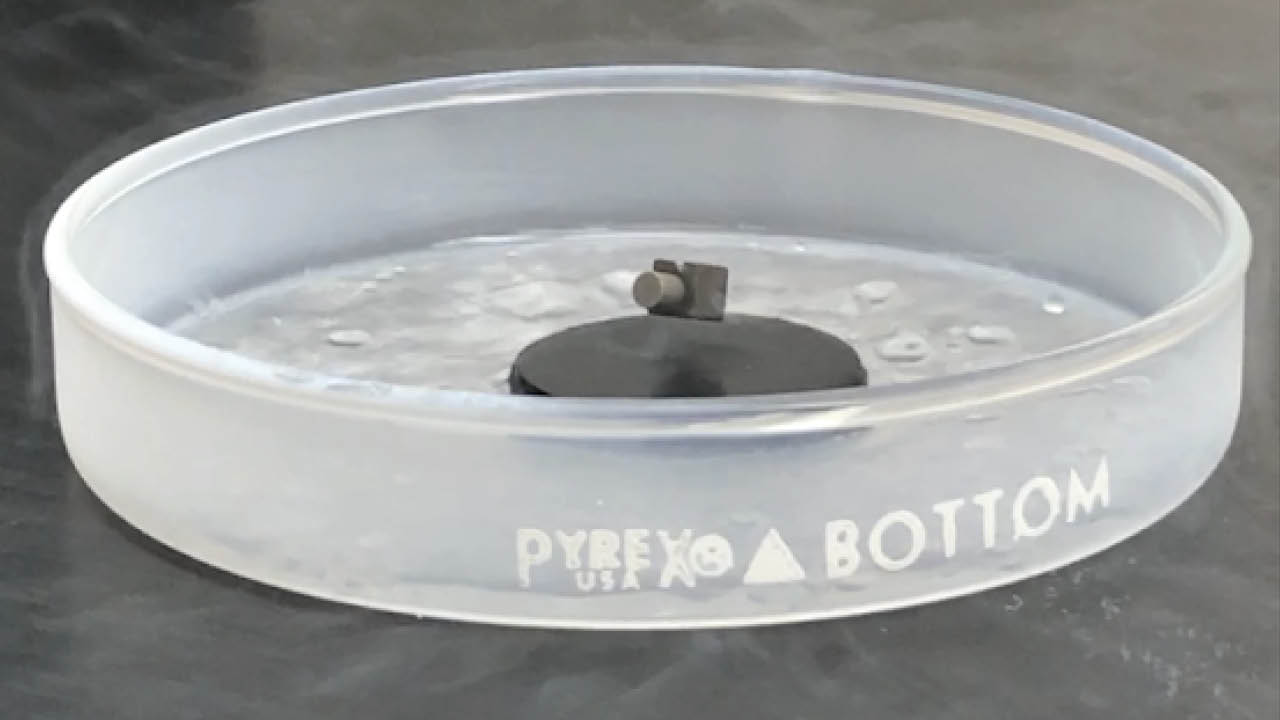

This Fall, two physics majors Nathan Arndt and Sarah Thornbrough worked in an Applied Superconductivity project to test the solid state fabrication conditions of metal-doped PBCO and high-temperature superconductor YBCO in a newly built/assembled Scientific Fisher Lindberg/Blue M high-temperature furnace. Various oxide chemical powders were ball milled together and fired in the furnace at 9500 C for 48 hours followed by annealing at 4500 C for another 24 hours and cooling down to room temperature. The heating profile was controlled via a Specview software as an interface between the furnace and the computer. Structure and purity of the synthesized oxides were checked by x-ray diffraction machine at the SC Johnson Integrated Science Lab. If impurities or undesired phases were detected, the powder would be again ball milled and the firing process would be repeated several times until the desired single (pure) phase was achieved. The resultant oxide powder was then pressed into the 2.54 cm diameter ceramic disc using a hydraulic press. These discs were used for magnetic levitation demonstrations during the CNHS open house.